COMPONENTS FOR THE SHEET METAL, STRIP AND WIRE INDUSTRY

We offer customized solutions for the efficient processing of sheet metal, strip and wire. Our portfolio includes:

Shears - precise cutting of strips and sheets in continuous or intermittent processes

Storage towers & belt storage - buffering for uninterrupted processes

Decoiler & spooler - reliable decoiling and recoiling of belt material

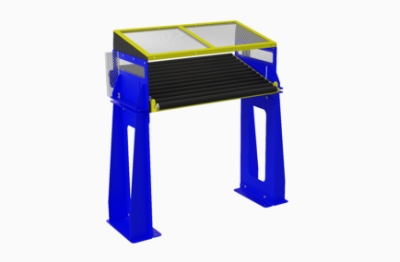

Roller conveyors & conveyor technology - smooth material flow between the processing stations

SHEARS & COMPLETE SYSTEMS FOR SHEET METAL PROCESSING IN MECHANICAL ENGINEERING

Our specialized shearing units and complete solutions are designed for the precise processing of sheet metal in industrial mechanical engineering. Whether rivet punch joints with integrated pressure roller or scrap shears for clean separating cuts - our systems guarantee high process reliability, repeat accuracy and optimum integration into automated production processes.

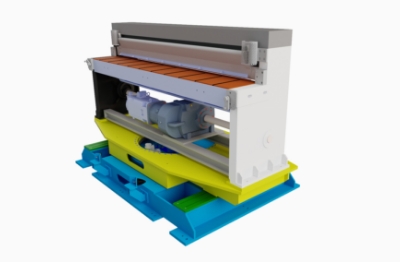

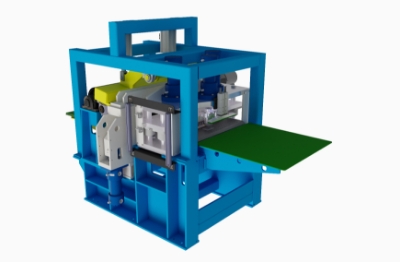

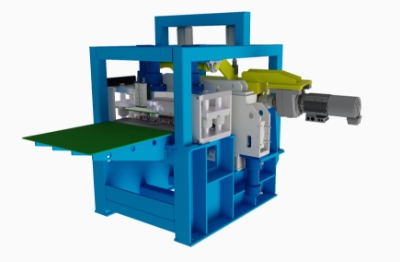

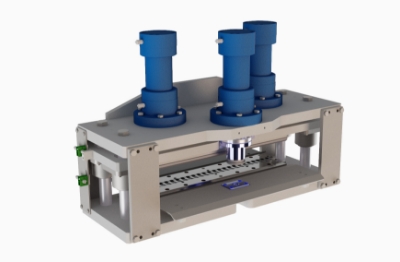

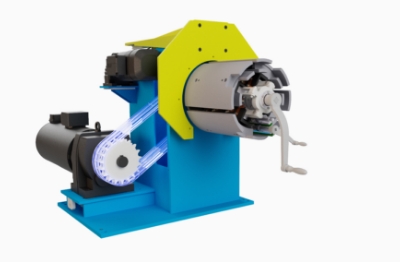

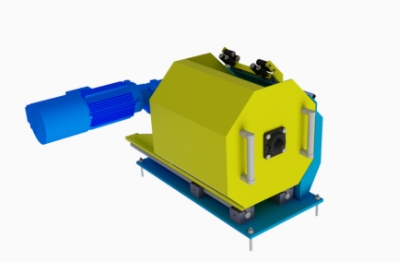

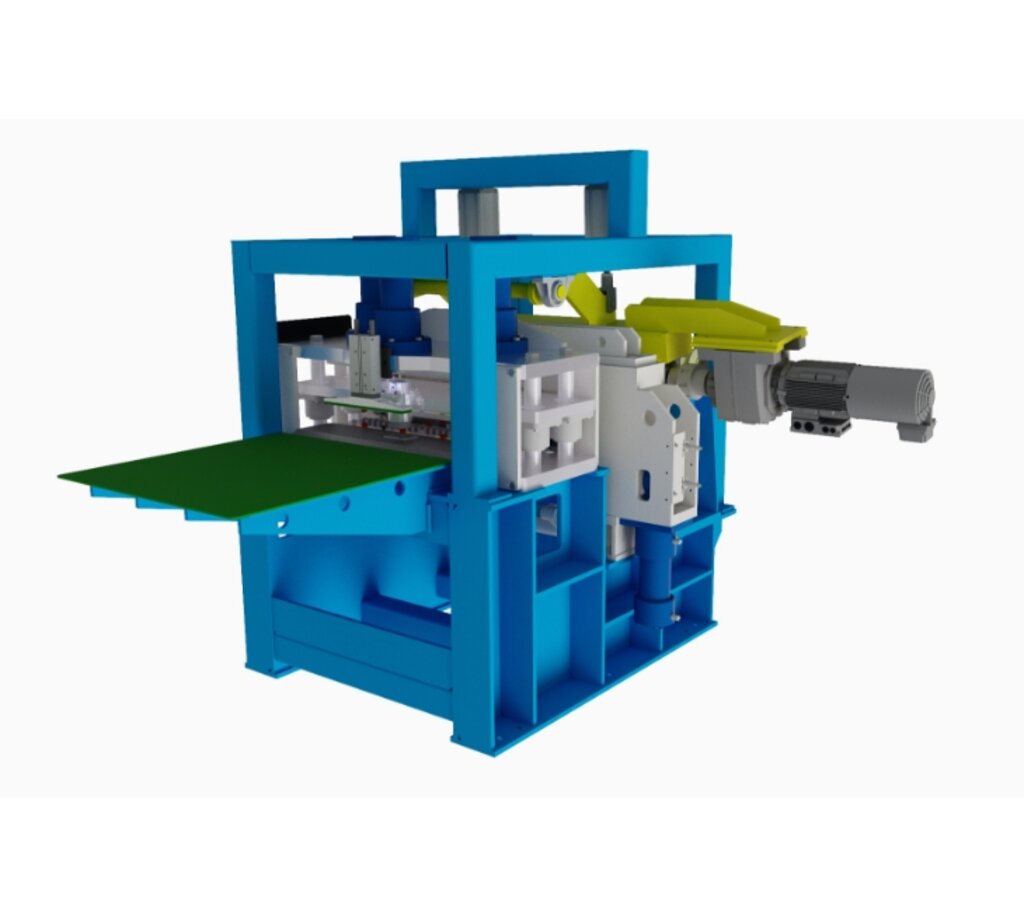

RIVET PUNCHING UNIT WITH SCISSORS AND PRESSURE ROLLER

This unit connects two sheet ends with a positive fit using a special geometry of the punching tool - completely without rivets. The pressure roller fixes the sheets, while the scraper shears prepare the edges. During punching, the sheets are pulled into each other by the tool shape, creating a permanent and stable connection.

ADVANTAGES:

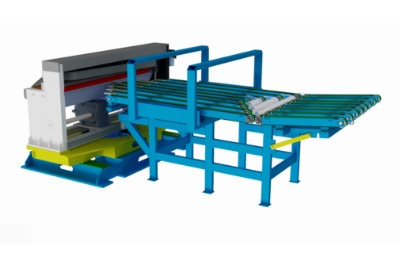

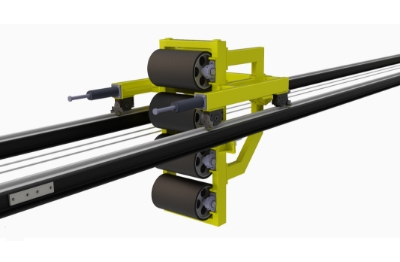

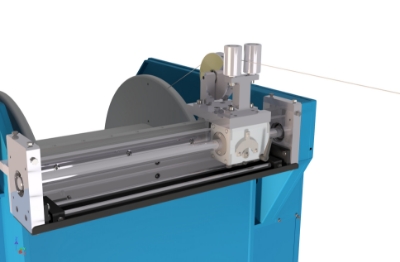

WIDTH ADJUSTMENT WITH GUIDE ROLLERS - PRECISE COIL GUIDANCE BEFORE THE SHEAR

Two laterally positioned guide rollers enable precise width adjustment of the coil after the snipping pit and before the shears. The rollers center the coil to protect the material and ensure stable guidance - for precise cuts and optimum process reliability.

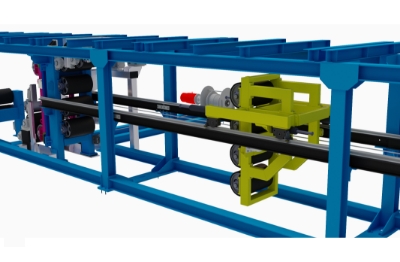

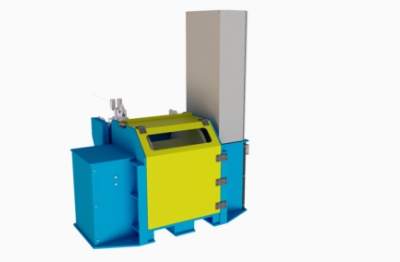

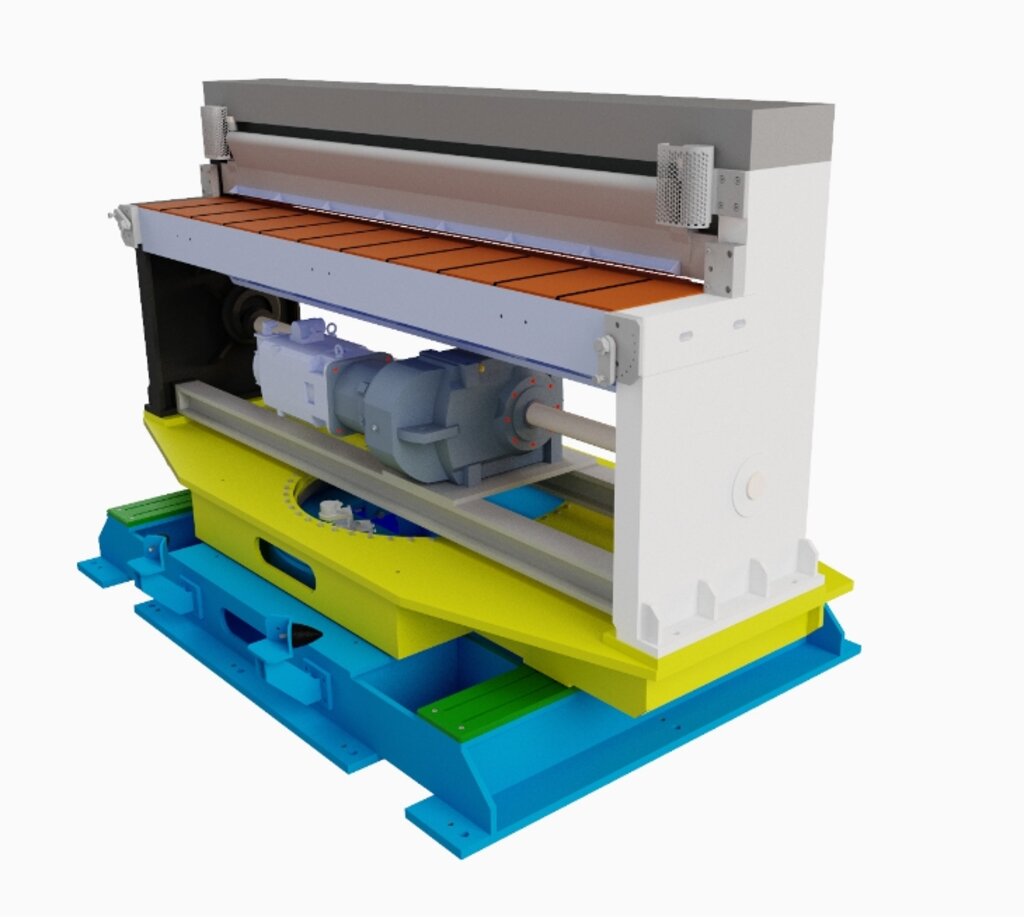

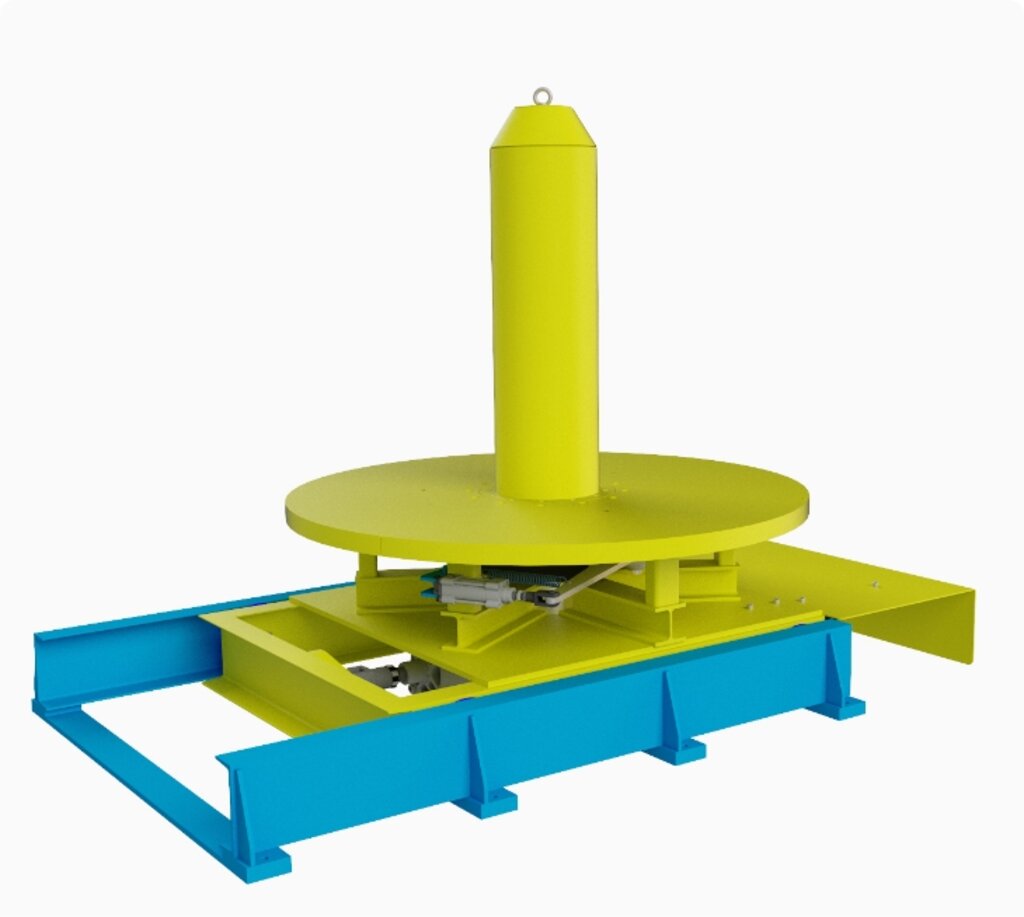

STORAGE TOWER FOR STRIP MATERIAL - EFFICIENT BUFFER SOLUTION FOR CONTINUOUS PROCESSES

A storage tower (also known as a belt storage or loop tower) enables the continuous supply of cutting systems, even if the material feed is interrupted. The production flow remains stable and efficient thanks to the targeted buffering of the strip material between two process steps.

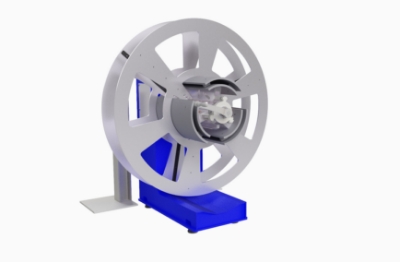

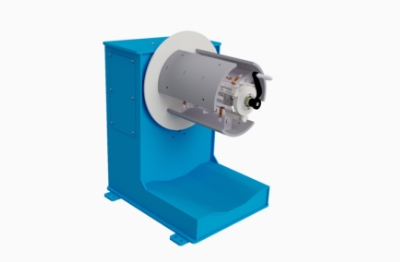

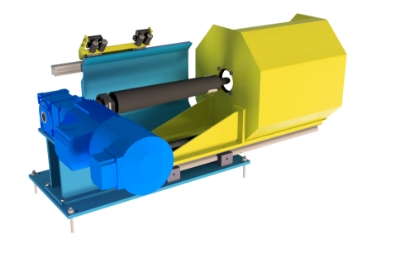

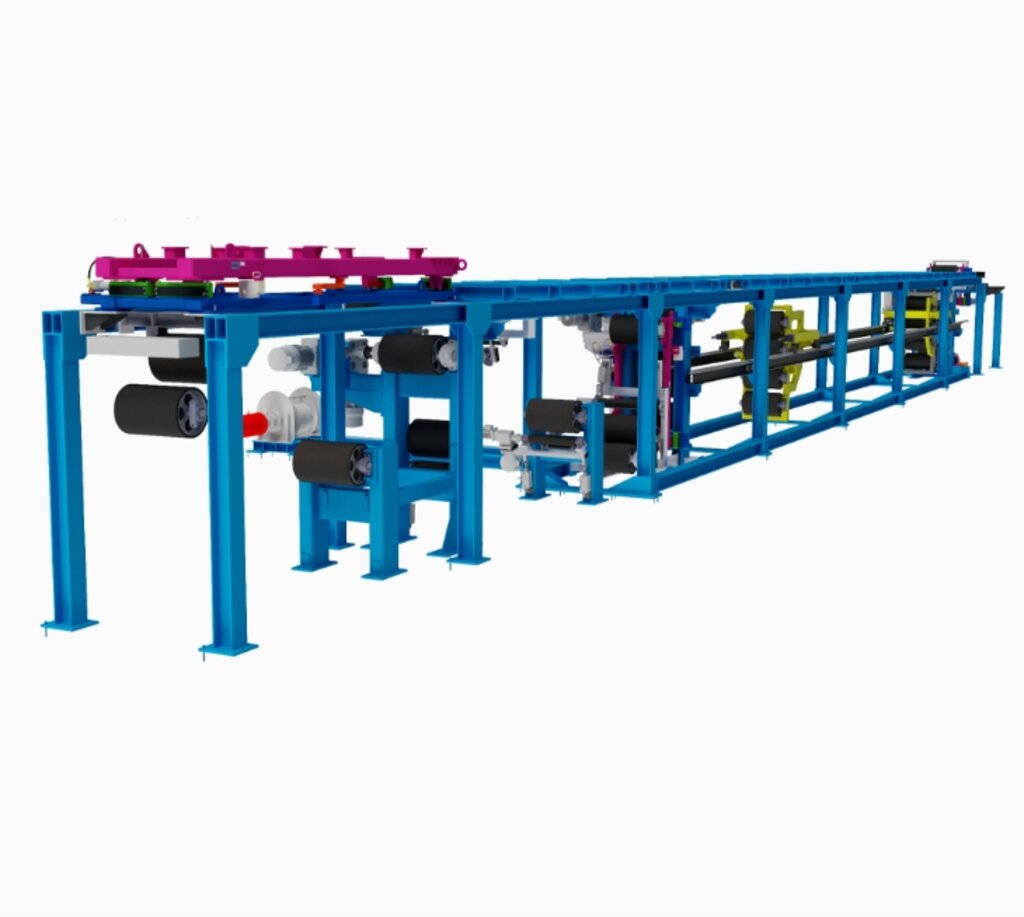

DECOILERS & SPOOLERS FOR WIRE, SHEET AND STRIP - FROM SMALL TO 30,000 KG

Our decoiler and spooler solutions enable the efficient decoiling and recoiling of wire, sheet and strip materials - from small units to heavy coils weighing up to 30,000 kg. Whether for processing, storage or transportation, we offer robust, precise and adaptable systems for every application.

From manual decoilers to motorized heavy-duty systems.

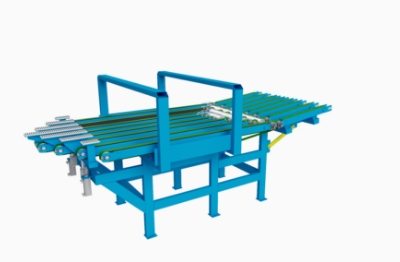

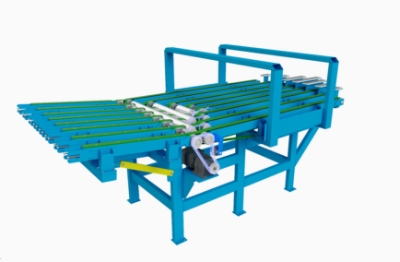

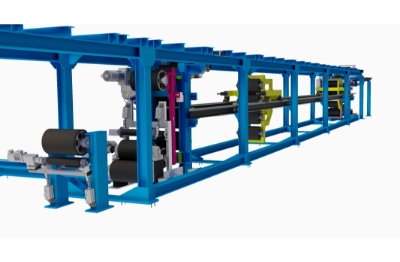

ROLLER TABLES, DEFLECTION ROLLERS AND S-ROLLER UNITS

In the sheet metal industry, roller conveyors ensure efficient and automated transportation of sheets and coils through the production lines. Deflection rollers enable precise directional guidance of the material and create flexibility in system planning. S-rollers are used for straightening and help to reduce tension in the sheet metal - for a smooth surface and optimum further processing.

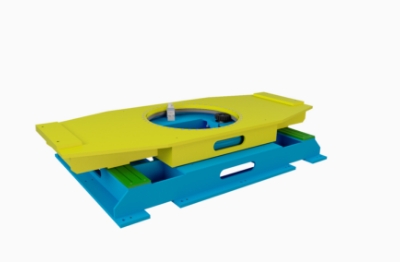

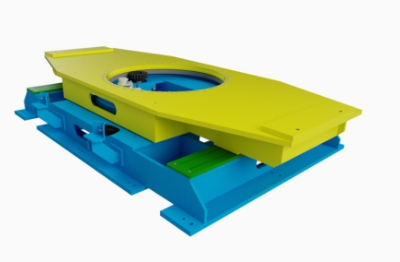

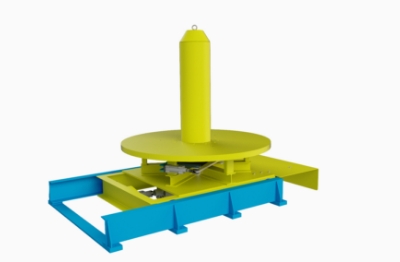

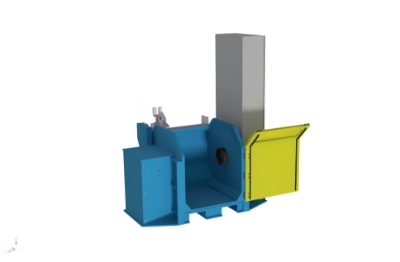

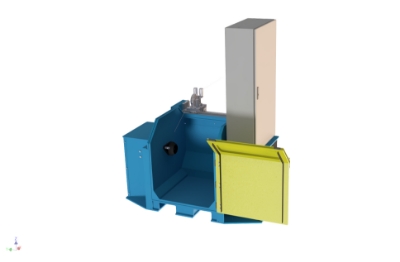

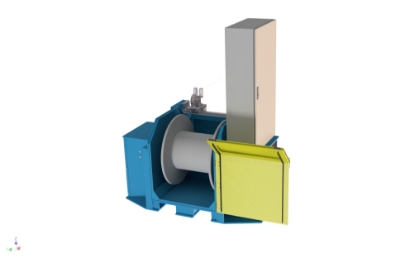

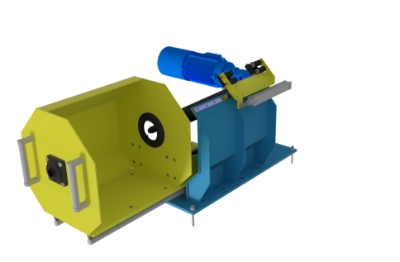

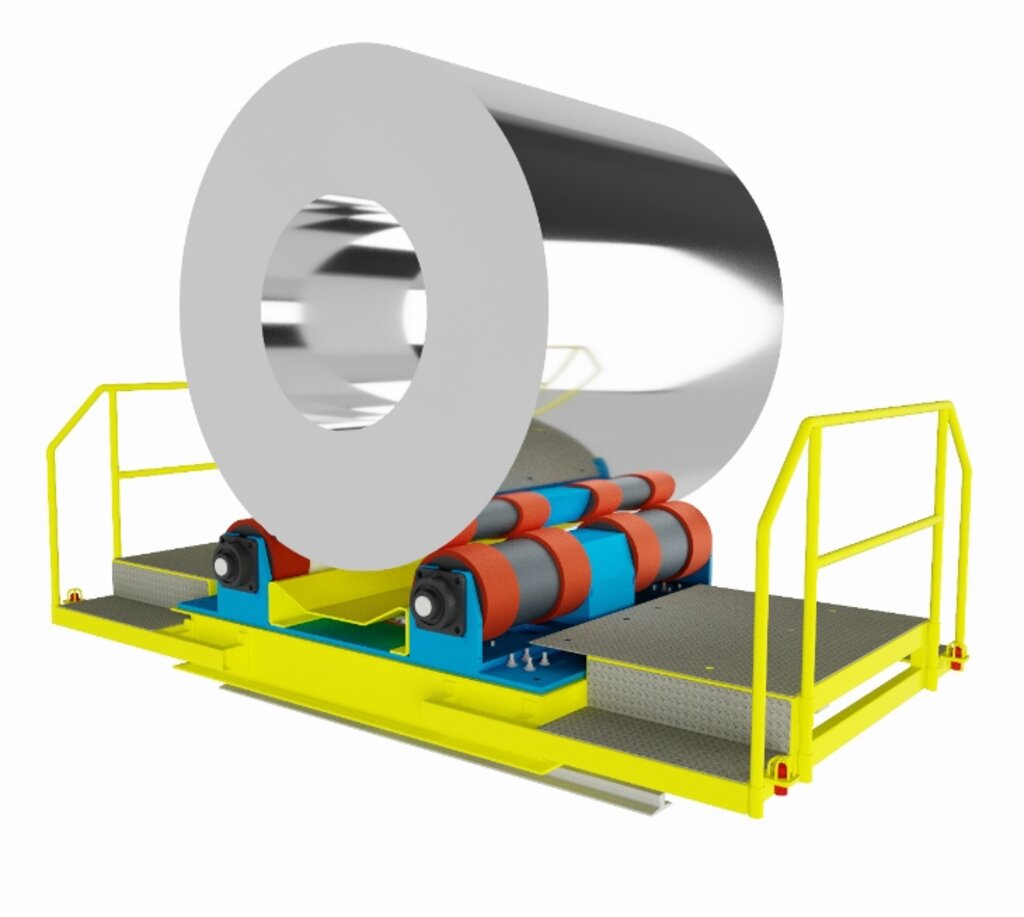

COIL TURNER UP TO 32 TONS - COMPACT & POWERFUL

Our coil turner enables the safe and efficient turning of sheet metal coils weighing up to 32 tons. Ideal for preparing machining processes, inspections or direction changes in the production line. Robust design, simple operation and maximum safety - for smooth processes in sheet metal processing.