DEBURRING/RUMMING DRUM FOR MASS-PRODUCED PARTS UP TO 4500 KG

Our high-performance deburring and rumbling drum is ideal for processing large quantities of piece goods - such as chains, forged parts or other mass-produced parts. With a loading capacity of up to 4500 kg, it ensures efficient deburring, smoothing and cleaning at high throughput rates.

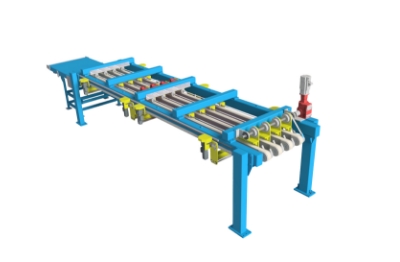

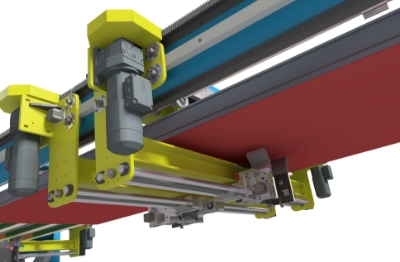

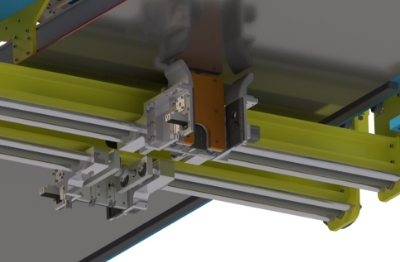

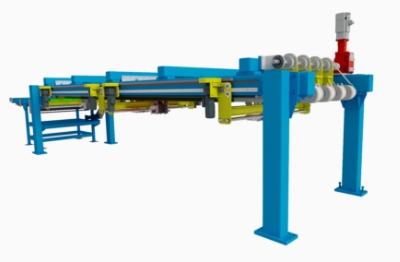

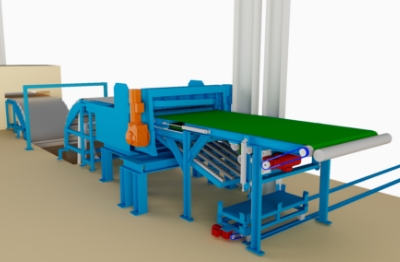

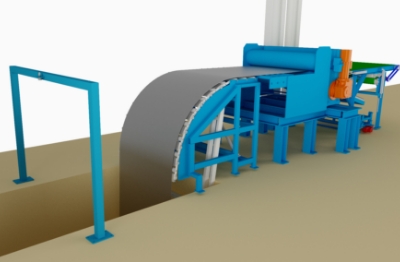

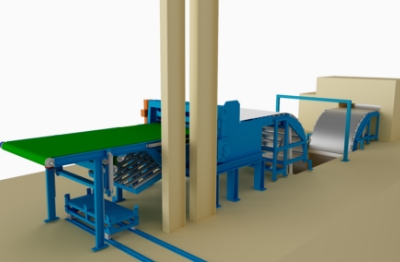

MAGNETIC BELT STACKERS FOR THE SHEET METAL INDUSTRY

Efficient. Precise. Automated.

Our magnetic belt stacker is the ideal solution for the automated stacking of sheet metal parts. Thanks to magnetic gripper technology and intelligent control, it ensures precise positioning, high process reliability and maximum productivity - perfect for modern production environments.

PATERNOSTER CABINET FOR KNIFE STORAGE IN THE SHEET METAL INDUSTRY

Our paternoster cabinet offers a space-saving and safe solution for storing cutting knives in sheet metal processing. Thanks to the vertical circulation system, all knives are ready to hand at all times - without bending down, stretching or searching. This significantly improves ergonomics at the workplace, reduces physical strain and increases efficiency. Ideal for structured, fast and back-friendly tool organization.

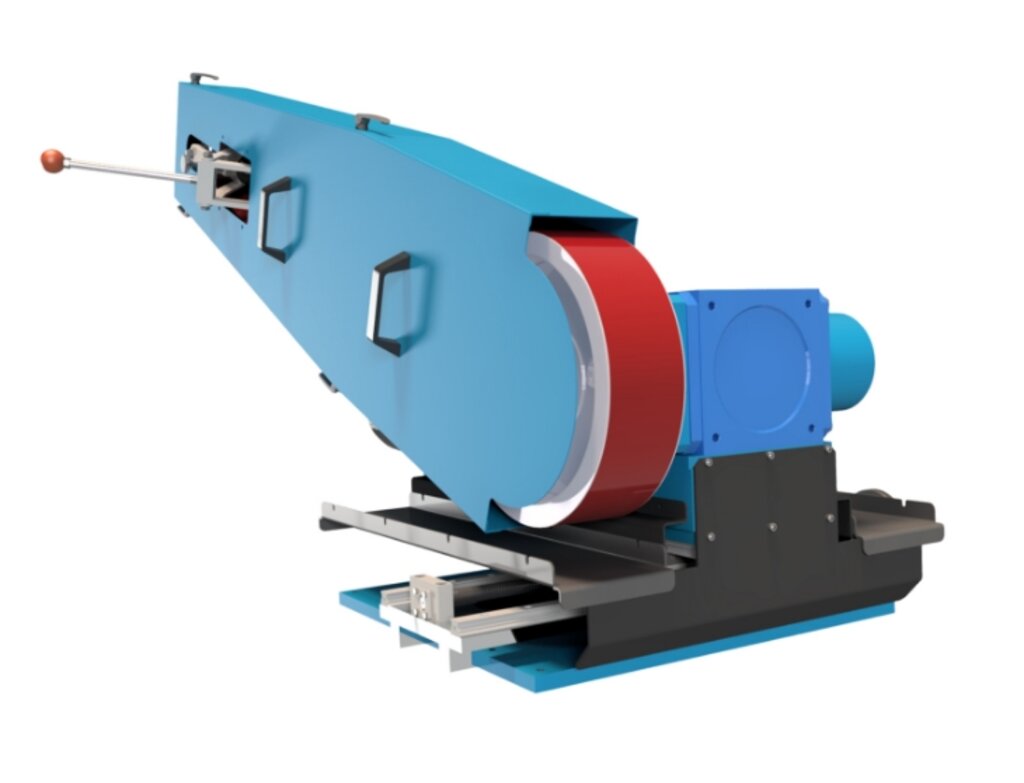

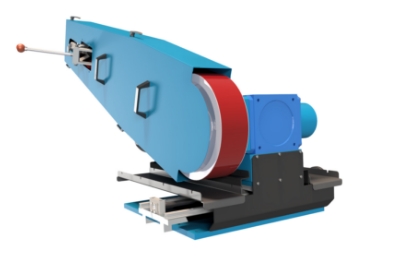

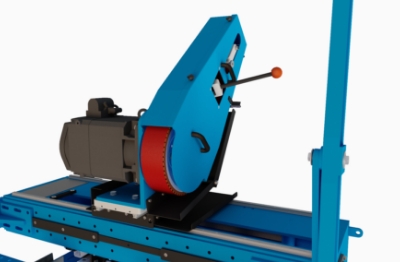

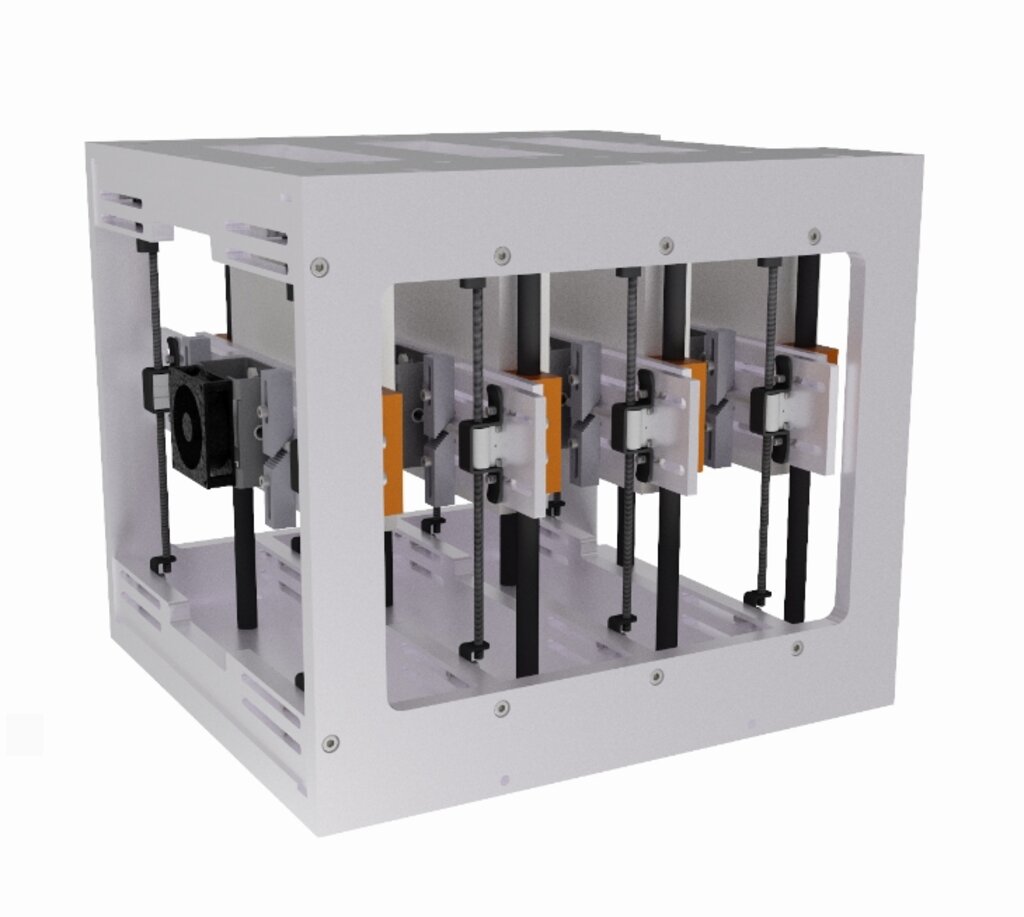

TEST BENCH FOR SMALL DRIVES

Compact. Versatile. Extremely resilient.

Our test bench for small drives enables precise functional and endurance tests under realistic conditions. The compact unit is designed for use in cold and heat chambers and reliably simulates extreme temperatures - ideal for development and quality assurance in demanding environments.

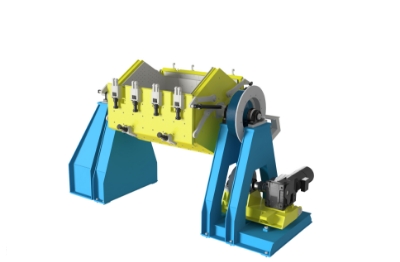

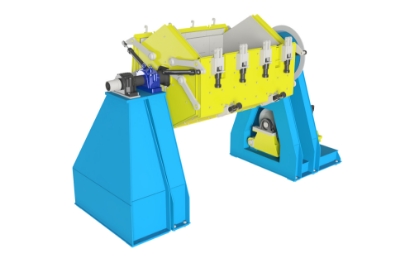

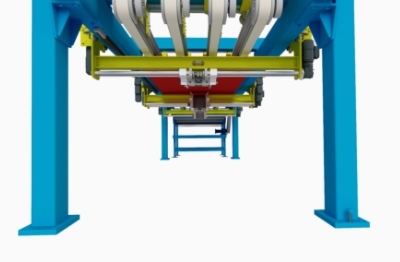

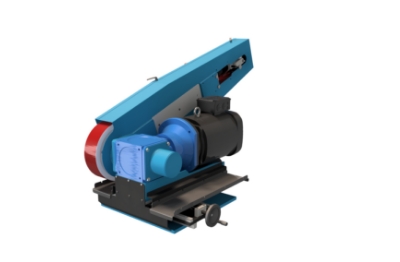

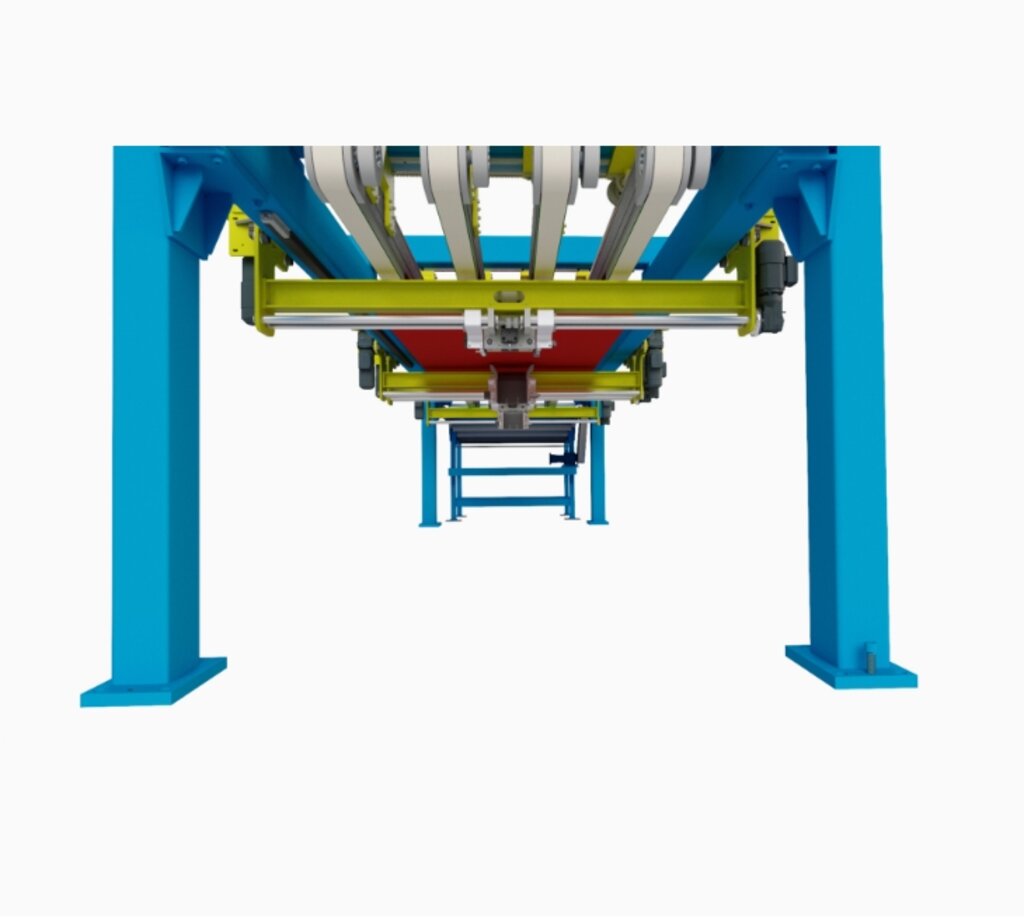

SPECIAL MACHINES FOR BEARING POINT MACHINING

Our special machines are specially designed for grinding bearing points and support rollers on rotary kilns in cement plants and on mills in incineration plants. They enable precise maintenance directly on site - efficiently, reliably and with minimum downtime.