INDIVIDUAL CONVEYOR AND HANDLING SYSTEMS FOR INDUSTRIAL PACKAGING PROCESSES

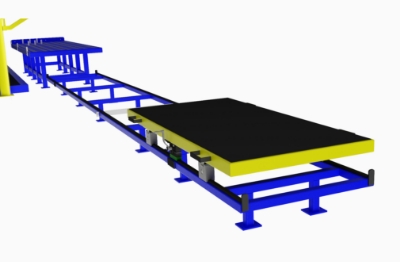

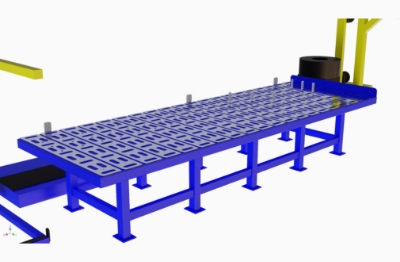

We offer customized components and assemblies for automated material handling - from roller conveyors, chain conveyors and turnstiles to compact handling systems. Our solutions can be used flexibly and are specially tailored to the requirements of the sheet metal industry and other sectors. Whether standard modules or custom-made products: We develop efficient systems for a smooth production process.

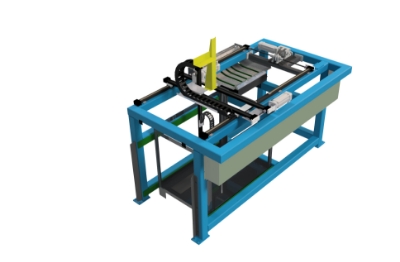

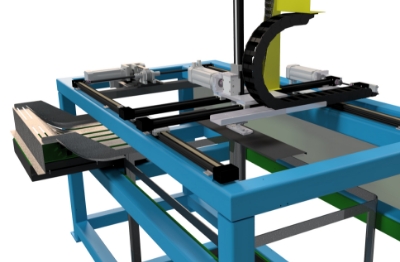

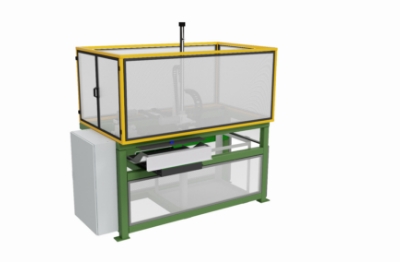

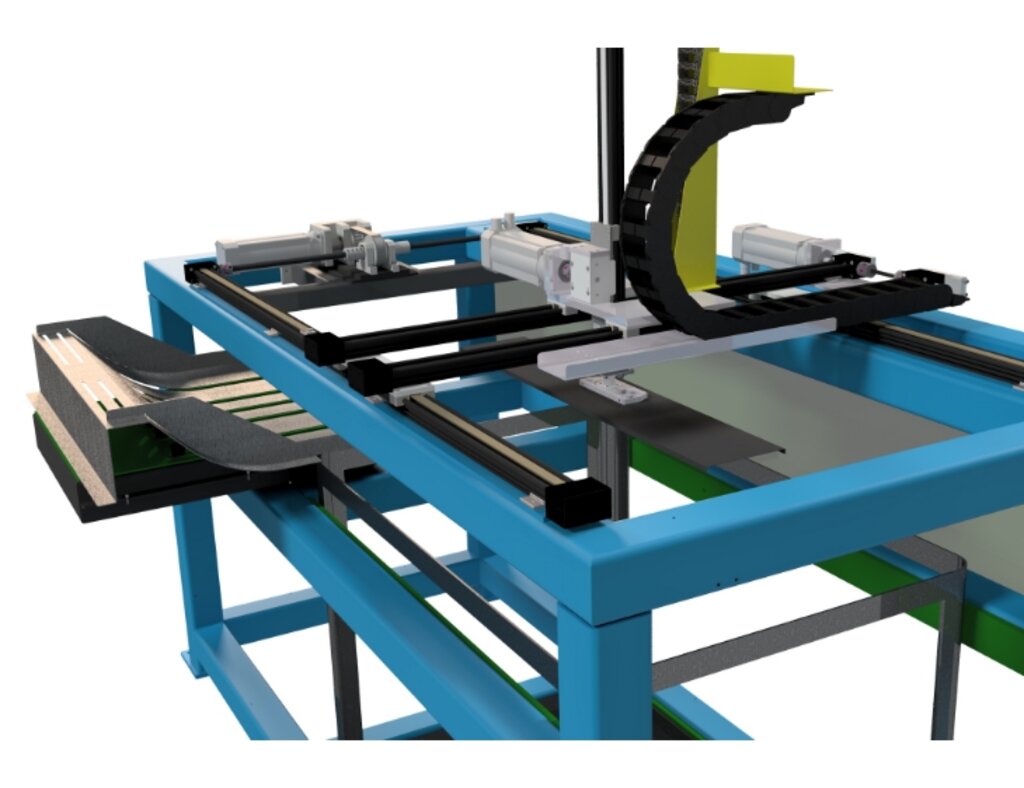

PACKAGING MACHINE FOR PRESSED PARTS AFTER PUNCHING

The automatic packaging machine is used for the automated pick-up, sorting and storage of punched pressed parts directly after the punching process. The parts are packed efficiently and securely in mesh boxes, reducing manual handling and optimizing the production line.